The Role of Thermopac’s Thermal Oxidizers in Industrial Air Pollution Control

Industries that deal with volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other industrial emissions must comply with stringent environmental regulations. One of the most effective solutions for air pollution control is a Thermal Oxidizer, a system designed to break down harmful pollutants through high-temperature combustion.

By efficiently converting hazardous compounds into harmless carbon dioxide (CO₂) and water vapor, Thermopac’s Thermal Oxidizer ensures cleaner emissions while helping industries maintain regulatory compliance. Their application spans various sectors, including pharmaceuticals, petrochemicals, food processing, and paint manufacturing.

This blog explores how Thermal Oxidizers work, their types, and their advantages in achieving sustainable industrial operations

The Importance of Thermal Oxidation

Uncontrolled industrial emissions can lead to:

- Environmental pollution, contributing to air quality degradation.

- Regulatory violations, resulting in heavy penalties.

- Health hazards, due to exposure to toxic gases.

- Operational inefficiencies, affecting production and compliance costs.

Thermopac’s Thermal Oxidizer is engineered to tackle these challenges by converting harmful gases into harmless byproducts like carbon dioxide and water vapor.

Working Principle of Thermal Oxidizer

Thermopac’s Thermal Oxidizer follows a high-temperature combustion process that ensures maximum pollutant destruction. The process consists of the following key stages:

1. Waste Gas Collection

Polluted gases from industrial processes are directed into the Thermal Oxidizer System, where they are prepared for combustion.

2. Preheating and Temperature Control

The gases are preheated using heat recovery systems to optimize fuel efficiency. The Thermal Oxidizer maintains an optimal combustion temperature (typically between 800°C to 1100°C) for effective breakdown of VOCs and HAPs.

3. Combustion and Pollutant Breakdown

Inside the combustion chamber, pollutants undergo high-temperature oxidation, where hydrocarbons and organic compounds are transformed into CO₂ and H₂O through a controlled reaction.

4. Heat Recovery and Energy Efficiency

To enhance operational efficiency, Thermopac’s Thermal Oxidizer integrates heat recovery units that capture excess energy and repurpose it for preheating or process heating applications.

5. Emission Purification and Release

Post-combustion, the gases pass through filtration and scrubbing systems to remove any residual particulates before safe atmospheric release.

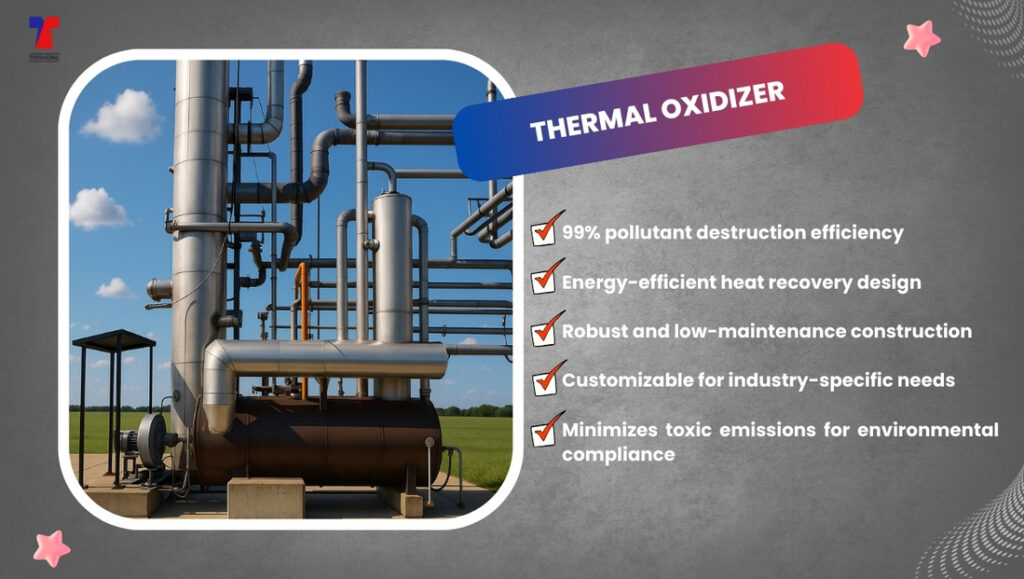

Advantages of Thermopac’s Thermal Oxidizer

✔ >99% Pollutant Destruction Efficiency ensuring regulatory compliance

✔ Energy-Efficient Design reducing fuel consumption through heat recovery

✔ Robust Construction for durability and low maintenance costs

✔ Customizable Solutions tailored to industry-specific requirements

✔ Enhanced Environmental Protection by minimizing toxic emissions

Applications in Various Industries

Thermopac’s Thermal Oxidizer is widely used in:

- Re-refining and oil processing plants

- Petrochemical and chemical manufacturing

- Pharmaceutical and food processing industries

- Paint, coating, and printing industries

Conclusion

Industrial emissions pose serious challenges, but Thermopac’s Thermal Oxidizer offers a highly effective and energy-efficient solution. With its superior pollutant destruction capability and heat recovery technology, Thermopac helps industries achieve cleaner emissions, regulatory compliance, and enhanced operational efficiency.

Contact us today to learn how Thermopac’s Thermal Oxidizer can benefit your operations!