LATEST NEWS

Home ≫ About Thermopac >> Latest News

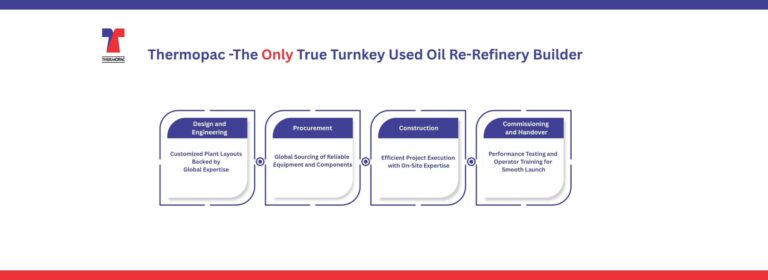

Selecting the right capacity for a used oil re-refining plant is one of the most critical steps in setting up or expanding operations. A plant that is too large may increase capital costs and remain...

In today’s fast-evolving industrial landscape, flexibility and scalability is the key to long-term success. This is especially true in the used oil re-refining sector, where feedstock availability...

Introduction: Turning Waste into Value In today’s refining and re-refining industries, efficiency and sustainability go hand in hand. One of the most pressing challenges faced by operators is the...

Why Transformer Oil Recycling Plant is the Future of Power Reliability The Growing Challenge with Transformer Oil Transformer oil is the lifeline of power equipment, providing insulation, cooling, and...

In an era of heightened environmental awareness and sustainability mandates, industries worldwide are under increasing pressure to manage their waste streams responsibly. One such critical area is the...

The Economics of Used Oil Re-Refining: Turning Waste into Wealth Used oil re-refining is rapidly emerging as a financially viable and environmentally responsible solution for industries dealing with...

Quality Assurance in Re-Refined Oils: Meeting Industry Standards As industries transition toward sustainable operations, re-refined base oils have taken center stage in lubricant manufacturing. Yet...

Innovations in Re-Refining: The Future of Sustainable Lubricant Production As the world embraces a circular economy, re-refining of used lubricating oil has emerged as a pivotal innovation in the...

Meta Description: Discover where Thermopac’s Lube Oil Blending Plant is applicable across industries. Learn how its precision blending technology ensures high-quality lubricants for automotive...

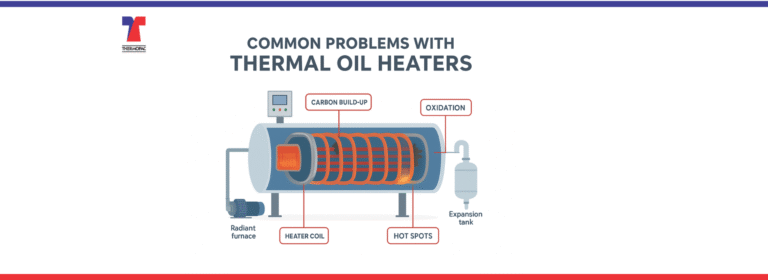

Understanding the Challenges Thermal oil heaters are built for reliability and long-term performance, but like any industrial equipment, they can develop issues if not maintained correctly. In...

As industries worldwide strive for sustainability, THERMOPAC stands at the forefront with its cutting-edge used motor oil recycling plants. Designed to maximize the recycling of used engine oil in an...

Introduction In the refining and re-refining industries, separating water from naphtha is a crucial step in ensuring fuel purity, process efficiency, and equipment longevity. Thermopac’s Water-Naphtha...

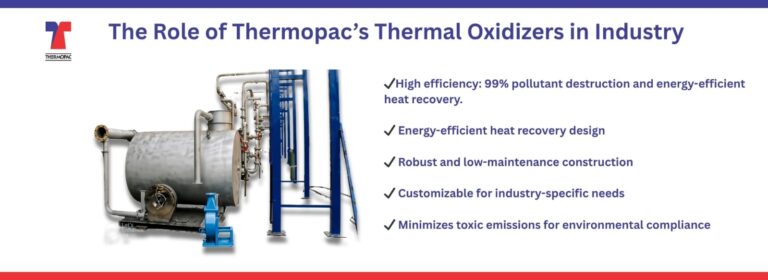

Industries that deal with volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other industrial emissions must comply with stringent environmental regulations. One of the most...

Fully Automated Plants for High-Efficiency Production In the industrial world, the importance of high-quality lubricants cannot be overstated. Grease, a crucial component in machinery maintenance...

Lubrication is the lifeline of machinery across industries. Whether it is automobiles, heavy-duty industrial equipment, or marine engines, the efficiency and longevity of these systems largely depend...