Slop oil contains hydrocarbons, solids, and water. Normally it appears as an emulsion that is not easily breakable. When the slop oil contains resins, tars, and surfactants, separation in conventional static settlers may take several hours to separate into components.

The objective of the THERMOPAC Separation System is to recycle the slop oil into the re-refining process for the recovery of light hydrocarbons, the base of oils, and finally polishing; or to mix it with normal crude oil for further processing.

- Pre-treatment which involves

- Heating the slop oil to reduce viscosity.

- The addition of chemical emulsion breakers/demulsifiers which help to improve separation

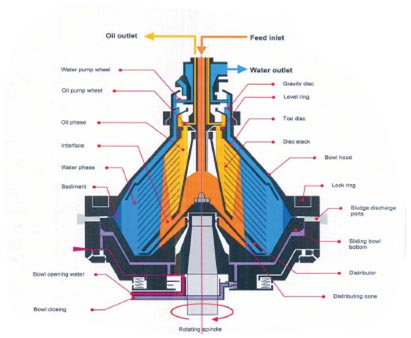

- A three phase decanter, which separates slop oil into three components consisting of oil, water and solids. This decanter is the core of the separation system

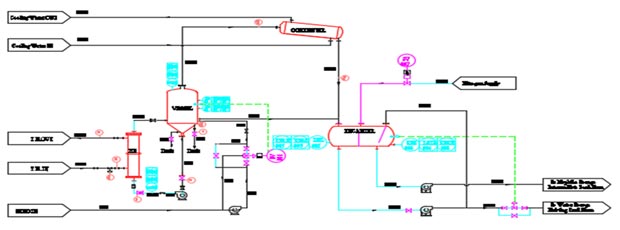

THERMOPAC separation system generally comprises the following steps:

- Separation of residual water, light hydrocarbons such as naphtha and gas oil; and base oil plus residue from the oil recovered from the process as above

- This process is carried out in a self-contained skid which houses a flash evaporator, thermal oil heat exchanger, water/naphtha condenser, decanter, Gas oil evaporator, and gas oil condenser.

The system is designed to completely dehydrate the feed and to remove light hydrocarbons such as naphtha and gas oil and deliver a mixture of fractions of light and heavy lube oils along with asphaltic residue, which can further be treated in our thin-film evaporators for recovery of various cuts of lube oil and subsequent polishing.

THERMOPAC provides a complete system to treat slop oil, which contains hydrocarbons, solids, and water, appearing as an emulsion. Using pre-treatment steps like heating and chemical emulsion breakers, along with a three-phase decanter, we efficiently separate oil, water, and solids. The system ensures recovered oil meets refinery standards, ready for re-refining or further processing. Our advanced units, including flash evaporators and thermal oil heat exchangers, remove residual water and light hydrocarbons, delivering high-quality oil. Designed for sustainability, our solutions minimize environmental impact while maximizing efficiency.