WIPED FILM EVAPORATOR

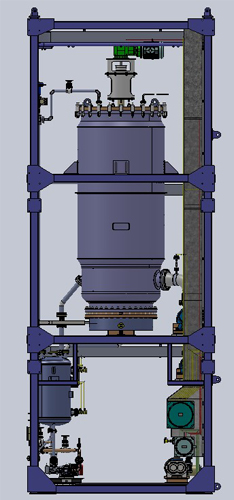

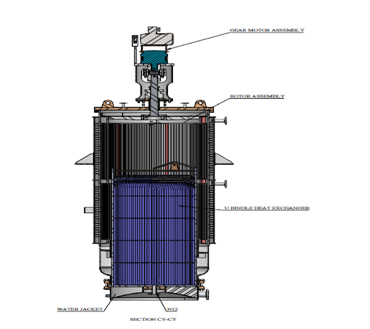

The thin film evaporator (TWE), which is the heart of the re-refining plant process, is a vertical cylindrical shell enclosed in a heating jacket with an internal electrically driven rotor evenly distributing a thin layer of oil on the heated wall by means of rotating wiper blades.

The heating medium, for example thermal oilcirculates though the jacket at high temperature. The lube oil passes through the evaporator’s internal heated wall; then a rotating entrainment separator with slotted wiper spreads the feed oil which is at an optimum temperature into a uniform thin film and continuously move even highly viscous lube oil down the heated wall. At this temperature and under vacuum, vaporized lube oil passes through the entrainment separator and condenses on the internal U-bundle condenser. The internal condenser reduces pressure losses and enables achieve high vacuum. The temperatures and vacuum are automatically monitored and controlled to obtain different cuts of lube oils. The base oils thus generated continuously pass on for storage and thereafter goes for polishing/finishing. Heavy components, additives, metals and degradation products are concentrated in the bottom residue. The bottom product is automatically transferred to storage tank.

The heating medium, for example thermal oilcirculates though the jacket at high temperature. The lube oil passes through the evaporator’s internal heated wall; then a rotating entrainment separator with slotted wiper spreads the feed oil which is at an optimum temperature into a uniform thin film and continuously move even highly viscous lube oil down the heated wall. At this temperature and under vacuum, vaporized lube oil passes through the entrainment separator and condenses on the internal U-bundle condenser. The internal condenser reduces pressure losses and enables achieve high vacuum. The temperatures and vacuum are automatically monitored and controlled to obtain different cuts of lube oils. The base oils thus generated continuously pass on for storage and thereafter goes for polishing/finishing. Heavy components, additives, metals and degradation products are concentrated in the bottom residue. The bottom product is automatically transferred to storage tank.

The unique features of Thermopac’s wiped/thin film evaporator are:

- Short residence time.

- Possibility of achieving high vacuum of the order of 0.001mbar.

- High rate of heat transfer through the film.

- Efficient and regenerative cleaning of the heating surfaces.

- Ideally suitable for heat sensitive products

- Completely indigenous technology

- Manufacturing the entire skid is in house.

- True turn key evaporator skid – Pre wired, pre insulated, and pre –painted along with necessary platforms and ladders.

- More than 50 units are in operation